THE BEST

THING IS TO GO WITH THE BEST.

The new autotec brochure

Download PDF

Five steps to the right

Product selection

More than just support.

Reliable. Global. Digital.

WELCOME

WE ARE YOUR LEADING PARTNER FOR AUTOMATED FASTENING

Process-reliable, efficient and well-founded solutions for every requirement.

WHEN KNOW-HOW MAKES THE DIFFERENCE.

INDUSTRY KNOW-HOW

FASTENING SOLUTIONS FOR INDUSTRIAL WOOD PROCESSING.

Industry expertise that makes your automated production reliable.

Prefabricated house construction

autotec knows the special challenges in prefabricated house construction – from cycle production and high tolerance requirements to flexibility with changing element sizes. The solutions from autotec enable precise, fast and secure fastener placement, adapted to individual requirements and processes. The result: reduced cycle times, less rework and a measurably higher output with consistently high quality.

Furniture industry

High-performance devices for the series production of furniture: autotec offers tailor-made fastening solutions for automated and semi-automated production. Our technology can be precisely adapted to the workpiece and processes, reduces manual work steps and ensures permanently stable connections – for high-quality products of consistently high quality thanks to optimized production processes.

Crates & pallets

In the production of crates, pallets and wooden packaging, speed, robustness and cost control are essential. autotec supplies reliable technology for demanding cycle times – from individual machines to the assembly of fully-automated production lines. Our systems are designed for tough industrial use, are easy to integrate and easy to maintain. This enables economical production with maximum reliability.

FAQ

WHICH FASTENING TECHNOLOGY SUITS MY APPLICATION?

Five steps to the right product selection.

Which fastener should be used?

How many fasteners need to be processed per cycle or shift?

Are there special structural conditions?

How much space is available for the appliance?

Which additional functions are required?

Any questions?

We will be happy to assist you personally in selecting the optimum fastening solution. Get in touch with us! We will advise you individually and practically.

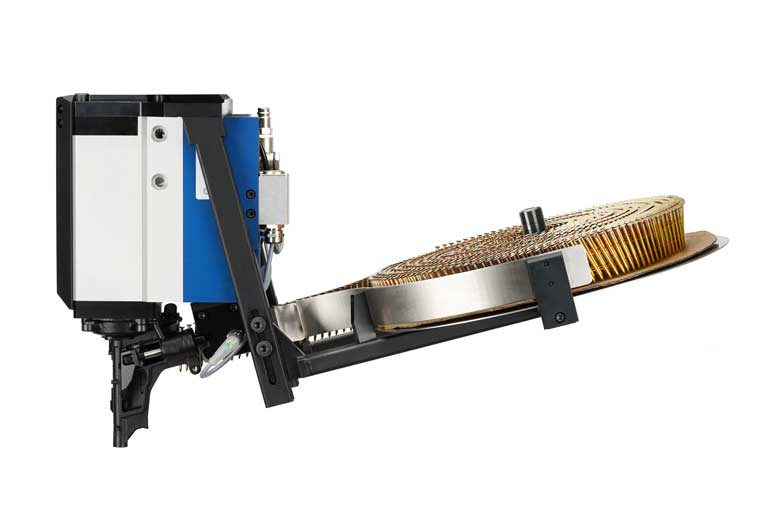

OUR SOLUTIONS

THE MOST DIVERSE PRODUCT RANGE ON THE MARKET

The right fastening solution for every requirement.

With our modular series, autotec offers the most comprehensive and flexible product range for automated fastening technology in industrial applications.

PRODUCT NEWS

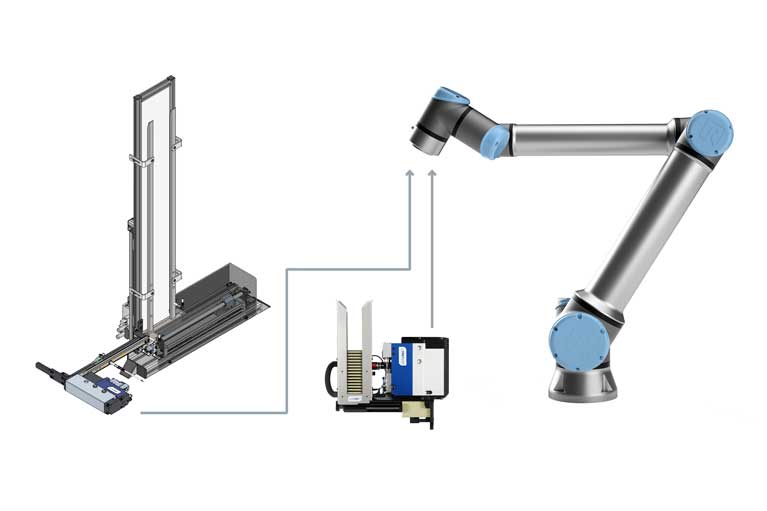

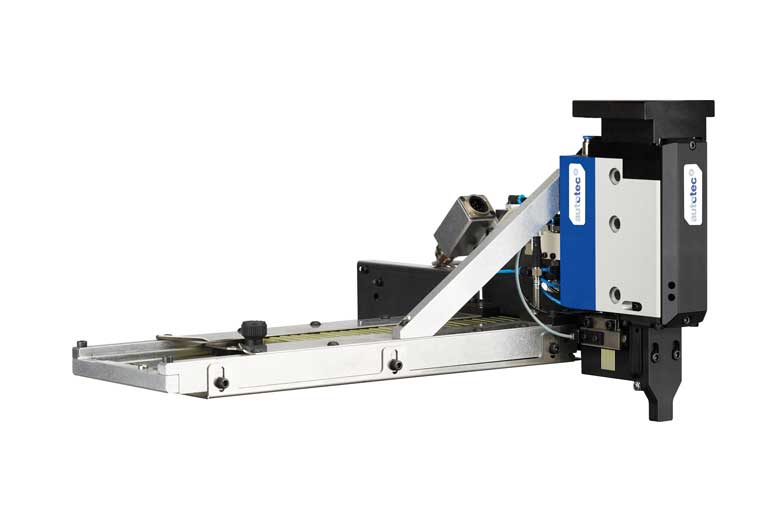

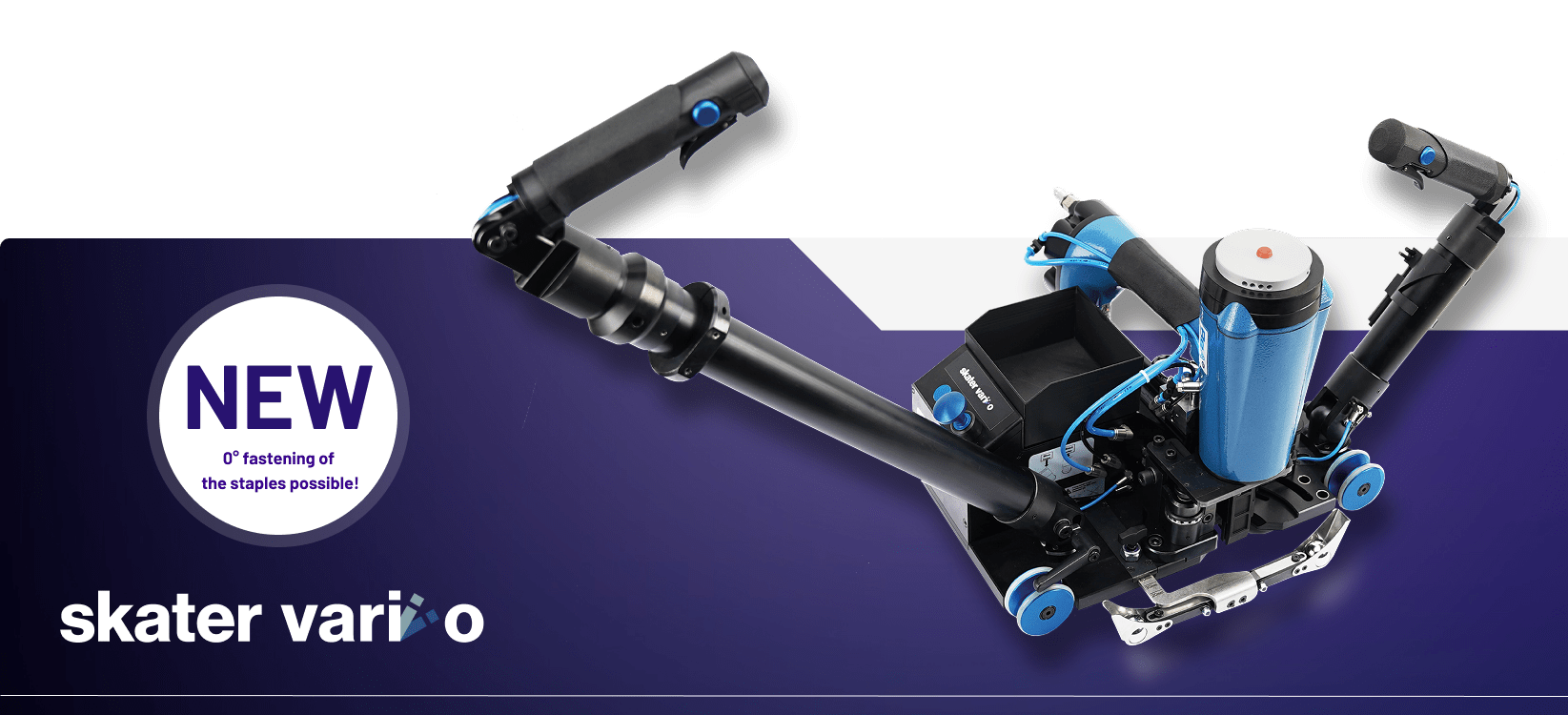

THE NEW AUTOTEC SKATER VARIO

Innovative skater technology for various stapling and nailing tools

Flexible mounting system

Precise series triggering

Ergonomic working

Individual configuration

Increased occupational safety

FASTENERS

TESTED QUALITY FOR BEST RESULTS.

Perfectly coordinated. Versatile. Reliable.

Staples

Our industrial staples, manufactured to the highest quality standards, guarantee maximum holding power. Whether in furniture construction, in the packaging industry or in prefabricated house or interior construction: rely on reliable connection technology for professional use. Perfectly matched to our devices, for efficient work without compromise.

Nails and pins

Our fasteners are made for durable connections on the construction site and in the workshop, robust and resilient. From timber frame construction to pallet production: With different types and lengths, we offer the right solution for every application.

Screws

Our screws stand for the highest quality for every project. You can rely on precisely manufactured threads and robust materials that hold reliably even under load.

SERVICE

MORE THAN JUST SUPPORT: RELIABLE. GLOBAL. DIGITAL.

Whether in person on site or digitally networked –

our service is as individual as your requirements.

Individual service that thinks along with you.

From planning to commissioning and far beyond: we support our customers with expertise, experience and genuine commitment. Our service begins with the first consultation and grows with your requirements. Whether training, maintenance or short-term support: We are there for you. Reliable, close and solution-oriented.

Strong worldwide. Personally close.

With 14 branches worldwide, exclusive sales partners and digital tools, we guarantee our customers a level of service that sets standards in over 60 countries. This enables us to provide support wherever you need it – fast, uncomplicated and always at eye level.

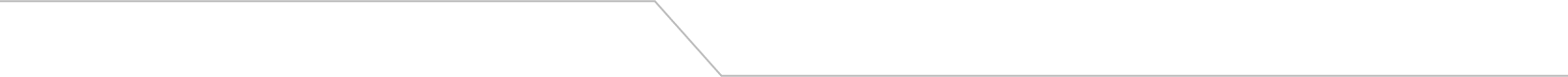

Digitally networked. The autotec Connector Box.

With the new Connector Box, we are taking service and process reliability to the next level: it networks autotec devices with the system and transmits relevant data in real time. This allows you to detect deviations at an early stage, avoid breakdowns and optimize maintenance with foresight. We also offer digital expertise in the BeAcademy that makes you independent. For efficient, smart service.

CONTACT

ALWAYS THERE. ALWAYS NEAR. YOUR DIRECT LINE TO US.

Whether you need advice or technical support – our team is there for you. Fast. Personally. Competent.

CONTACT

WORLDWIDE FOR YOU

Our global network offers you service and advice wherever you need us.

Belgium

Norway, Sweden

Denmark

France

United Kingdom

Italy

Canada, Mexico, USA

Czech Republic

Portugal, Spain

Slovakia

Balkan States, Bulgaria, Estonia, Finland, Greece, Croatia, Latvia, Lithuania, Malta, Poland, Romania, Serbia, South America, Turkey, Cyprus